INDUSTRIAL AUTOMATION

AND MECHANICAL ENGINEERING

In that field, Aamec in Genk is your experienced and reliable all-in-one partner. Our projects are all tailor-made. With more than 25 years of experience, we offer you the expertise and service you expect from a highly specialized partner. From engineering and design, from in-house manufacturing and assembly to installation and after-sales service: we think along with you from A to Z.

INDUSTRIAL AUTOMATION

AND MECHANICAL ENGINEERING

In that field, Aamec in Genk is your experienced and reliable all-in-one partner. Our projects are all tailor-made. With more than 25 years of experience, we offer you the expertise and service you expect from a highly specialized partner. From engineering and design, from in-house manufacturing and assembly to installation and after-sales service: we think along with you from A to Z.

ACTIVITIES

ACTIVITIES

ENGINEERING & STUDY

Van losstaande studie tot uitgewerkte projecten.

Lees meer

Een eenmalige studie of conceptontwikkeling?

Een volledig afgewerkt turnkeyproject?

Het Aamec Engineering-team gaat met diepgaande en actuele kennis van zaken voor u aan de slag.

Wij focussen altijd op een totaaloplossing, die rekening houdt met alle bedrijfsomstandigheden en u op de lange termijn het beste resultaat garandeert.

SOFTWARE & AUTOMATION

De nieuwste technologieën voor een hoogstaande service.

Lees meer

Continu bijleren en verbeteren staat centraal bij Aamec.

Wij investeren in de kennis en opleiding van medewerkers om aan elke automatiseringsvraag volgens de hoogste normen te kunnen voldoen.

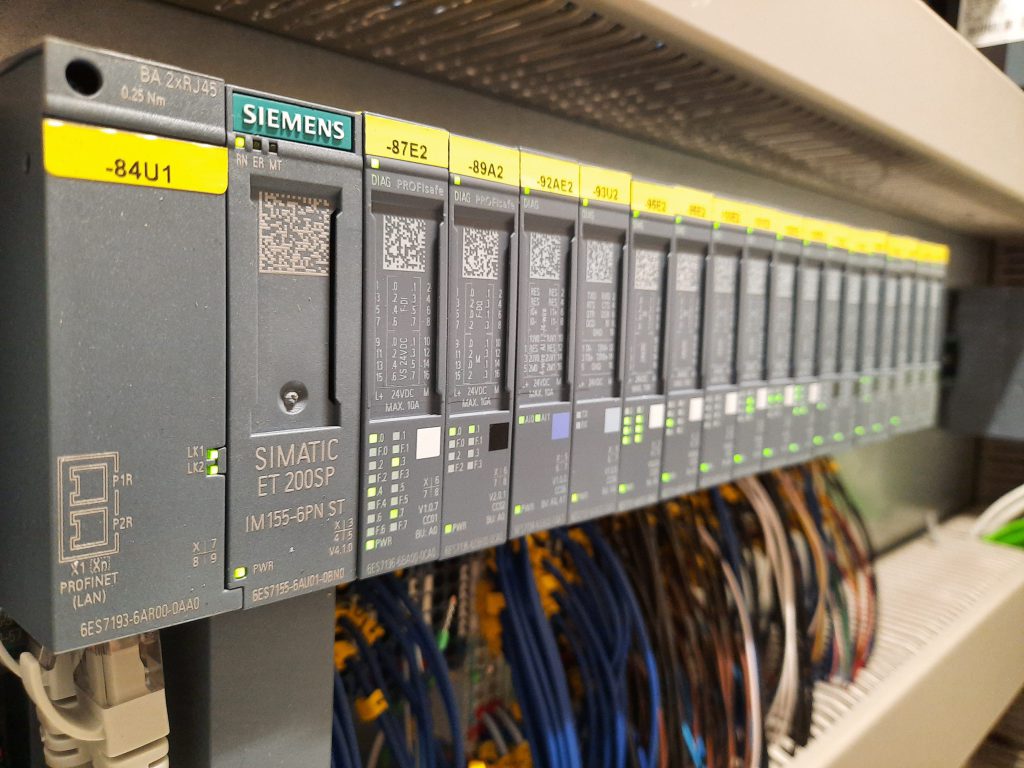

Van de laatste (Siemens) PLC software tot E-plan.

Samen met u ontwikkelen we ook complete systemen voor traceability en zorgen voor de communicatie met nieuwe of bestaande robots in de productielijn.

ELECTRICAL CABINETS

Een elektrische expertise om u tegen te zeggen.

Lees meer

De engineers en technici zorgen voor de complete elektrische omkadering van uw installaties.

Wij ontwerpen de elektrische schema’s, assembleren en bekabelen de elektrische kasten en verzorgen de hardware ‘in the field’.

Ook beschikt Aamec over het UL certificaat (voor elektrische borden voor de VS) en een specifiek meettoestel voor aarding- en isolatiemetingen.

MECHANICAL DESIGN

Van prototype tot productielijn.

Lees meer

Elk product, elk bedrijf is anders. Vertrouw op de ervaring van Aamec om uw noden juist in te schatten en een oplossing op maat voor te stellen.

We optimaliseren uw bestaande installaties of ontwerpen nieuwe systemen.

Ons ervaren team van designers werkt daarvoor in de laatste versie van Autodesk Inventor (sterkteberekening, complexe 3D weergaven, CAD-ontwerp en productietekeningen).

PROJECT MANAGEMENT

De sleutel tot een succesvolle samenwerking.

Lees meer

Het succes van elk project staat of valt met een goed beheer en opvolging.

Uw projectmanager bij Aamec fungeert als single point of contact, bewaakt nauwgezet alle specificaties en communiceert proactief over de voortgang van het project.

CE – NORMALISATION

MACHINE CONSTRUCTION & ASSEMBLY

Ook voor onderhoud, herstellingen, storingen of zelfs de verhuis van installaties staat Aamec voor u klaar.

MANUFACTURE & CNC OPERATIONS

Alles onder één dak: een grote troef voor u.

Lees meer

Titel

Subtitel

Some text in the Modal..

REALISATIONS

OUR WORK

REALISATIONS

OUR WORK

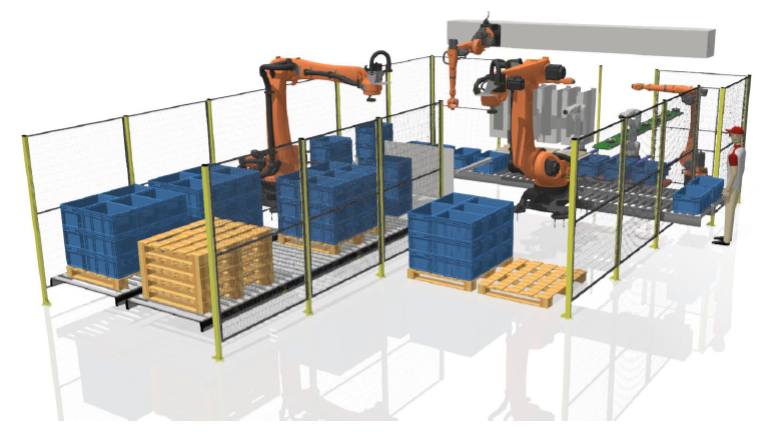

Aamec supplies automotive suppliers all over the world. This ranges from process, handling and assembly lines with robots for petrol tanks to assembling engines, rear axles and dashboards.

Automotive

In addition to the automotive industry, Aamec designs and realizes specific installations tailored to the customer in a wide range of industrial branches. Our engineers develop packaging lines, laminating installations, transport systems and assembly tables, among other things.

Non-automotive

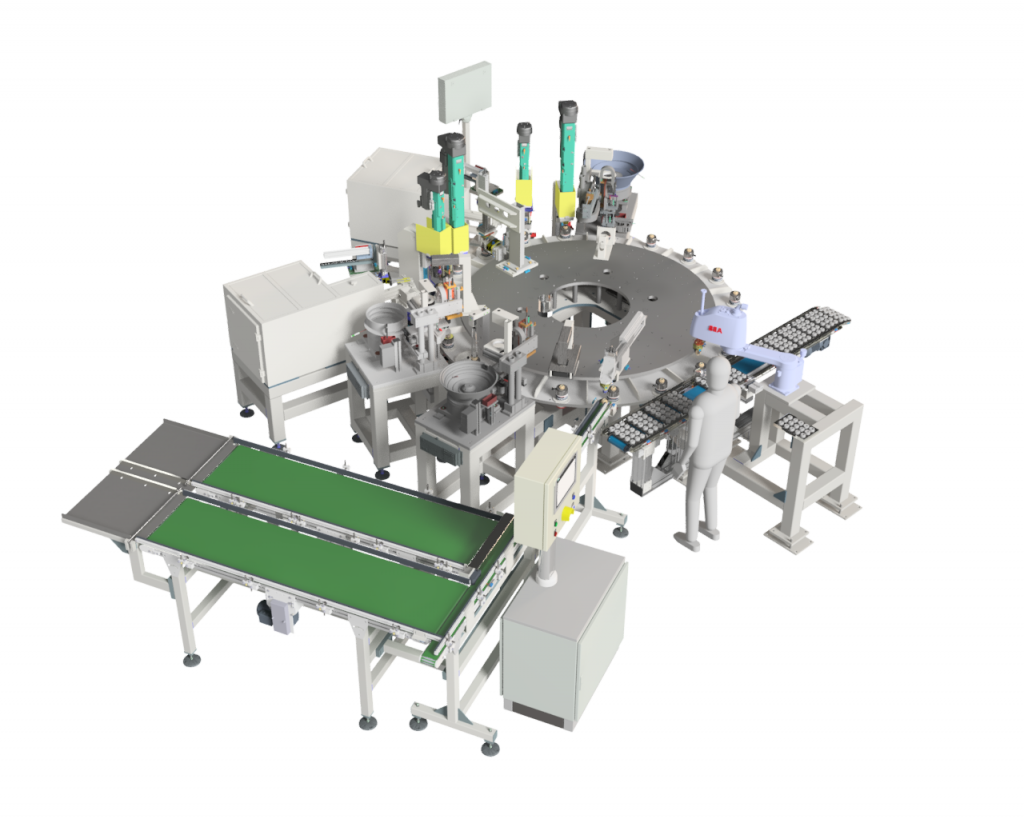

The servo-controlled turntable ensures that multiple operations can be performed simultaneously. The various parts are supplied by vibratory fillers and conveyor belts. The electronic spindle-driven presses ensure accurate assembly. After a vision check by means of cameras, the pick & place is done with mini robots.

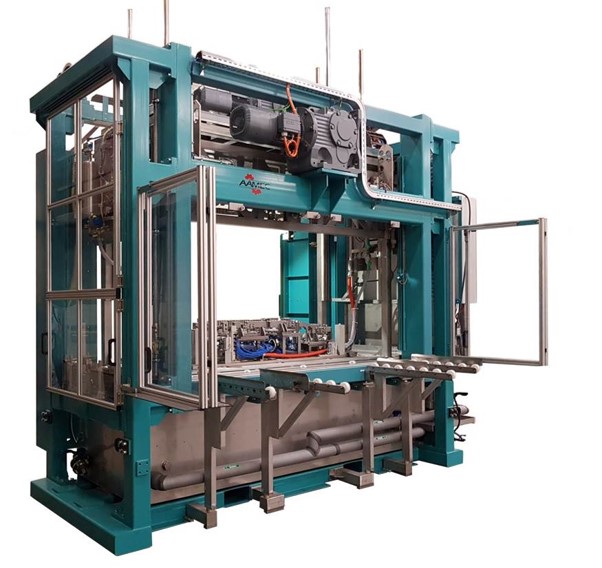

This installation provides the controlled cooling of blown plastic products. A standardized mold system and servo-controlled movements allow the machine to be loaded by robot or by an operator. A heat exchanger and a pump circuit of 3 pumps allow automatic air-conditioning. The machine contains an automated self-test to ensure safe operation at all times.

- Automatic pump assembly

- Welding station for valves by means of Hotplate welding

- Automatic screw feed by means of vibratory fillers

- Vision control for all mounted parts

CNC turning and milling work

Electrical installations and panel construction

Aamec owns an extensive machine park of 3 Leadwell 3-axis and 1 Edel 5-axis milling machine. All kinds of parts are manufactured with this, ranging from simple 2D parts to large welded frames and complex 3D shapes. The machines are controlled by the CAD / CAM package PrimCam or Hypermill in combination with Inventor. This makes it possible to simulate working times of complex parts.

- Aamec has 2 sawing machines, 1 automatic and 1 manual. These can be used to saw the wide stock of steel, aluminum and stainless steel.

- With the help of 2 professional welding tables and various welding equipment, Aamec offers the possibility of welding constructions, machines, platforms,… made of steel, aluminum or stainless steel.

- The wet coating department has a zone where the manufactured constructions can be painted manually in the desired RAL colors.

- stop time measurements of safety components (light curtains, floor scanners, …)

- Earth resistance of electrical installations

ABOUT US

GENERAL

AUTOMATISATION &

MECHANIZATION

Aamec (a Dutch acronym of General Automation and Mechanization), is located at the Industrial Zone South in Genk and was founded in 1994 by Freddy Baeten and Yvo Dreesen. With a partial management buyout in 2017 by Jo Vanbuel and Luc Stassen, Aamec was set on course for a stable future.

Over the years, Aamec has systematically invested in the expansion of the machinery, the company site and the number of employees, meanwhile a workforce of more than 30 motivated and highly specialized professionals.

The result? Today Aamec is able to carry out both small and complex, large-scale industrial automation and mechanization projects at home and abroad. In addition to complete turnkey projects Aamec also provides studies, concept development and realizations for external engineering agencies.

Aamec carries out the complete project realization in-house: welding constructions, milling and turning work, sheet metal work, electrical and PLC controls. The technical workshop is equipped with modern CNC processing machines.

Service is absolutely central to Aamec’s total approach. We go for a collaboration in which you are cared for and supported as much as possible. That is also one of the reasons why we opt for the complete management of your projects in-house.

ABOUT US

GENERAL

AUTOMATISATION &

MECHANISATION

Aamec (General Automation and Mechanization), located at the Industrial Zone South in Genk, was founded in 1994 by Freddy Baeten and Yvo Dreesen. With a partial management buyout in 2017 by Jo Vanbuel and Luc Stassen, Aamec was set on course for a stable future.

Over the years, Aamec has systematically invested in the expansion of the machinery, the company site and the number of employees, meanwhile a workforce of more than 30 motivated and highly specialized professionals.

The result? Today Aamec is able to carry out both small and complex, large-scale industrial automation and mechanization projects at home and abroad. In addition to complete turnkey projects Aamec also provides studies, concept development and realizations for external engineering agencies.

Aamec carries out the complete project realization in-house: welding constructions, milling and turning work, sheet metal work, electrical and PLC controls. The technical workshop is equipped with modern CNC processing machines.

Service is absolutely central to Aamec’s total approach. We go for a collaboration in which you are cared for and supported as much as possible. That is also one of the reasons why we opt for the complete management of your projects in-house.

Contact

AAMEC N.V.

Eikelaarstraat 21

Poort genk 5269

3600 Genk

info@aamec.be

T +32 (0)89 30 53 42

Contact

AAMEC N.V.

Eikelaarstraat 21

Poort genk 5269

3600 Genk

info@aamec.be

T +32 (0)89 30 53 42